Since the beginning, we’ve asked ourselves: what truly makes a great pair of swim trunks? Is it the intricate prints, the recycled materials, the superior craftsmanship and recycled materials, the durability and quick-dry performance, or the storytelling and philanthropy stitched into every pair? For us, it’s all of the above!

So let’s dive into how we make our ‘Staniel’ swim trunks.

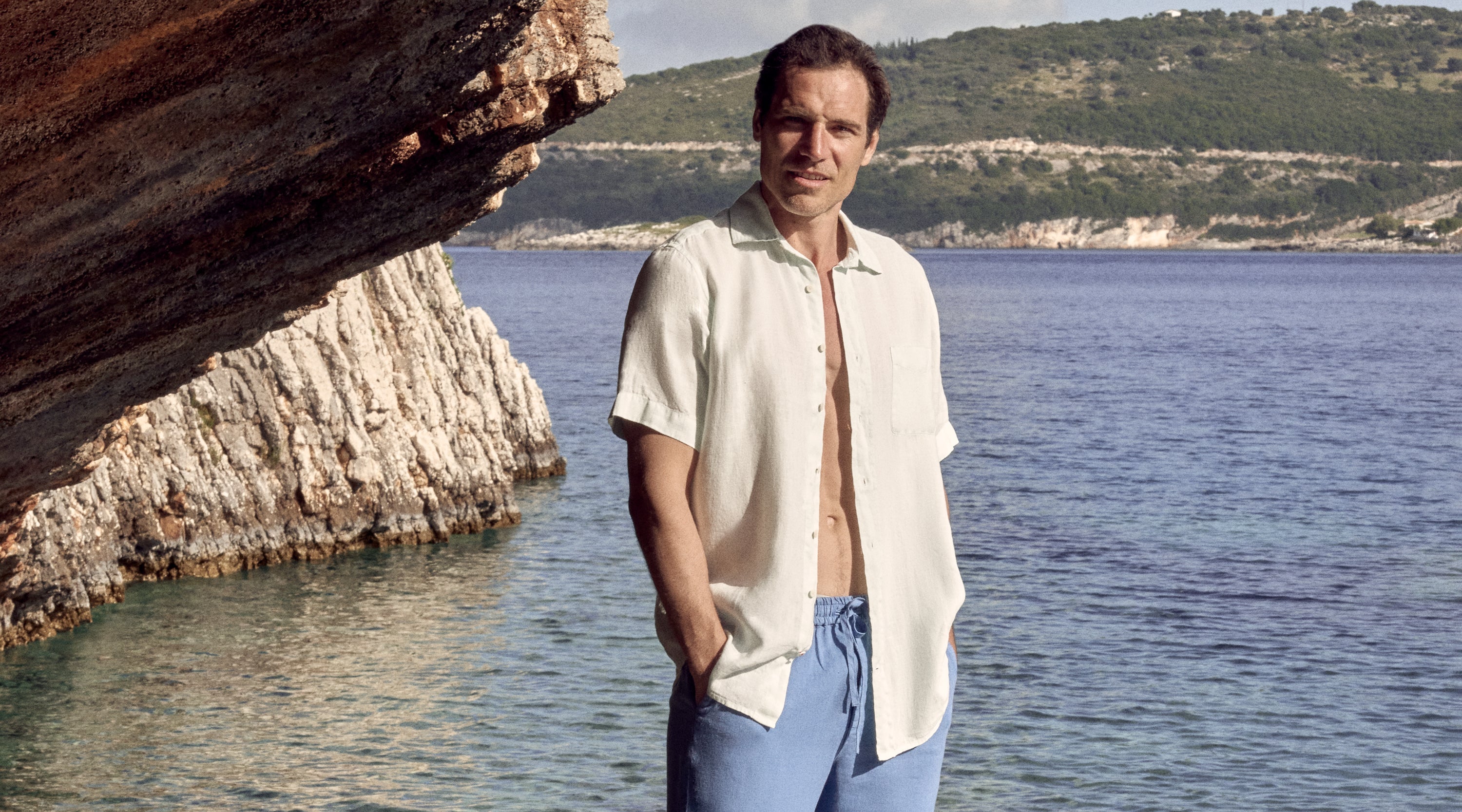

Models wear 'Elephant Palace Blue' Staniel swim shorts with matching 'Elephant Place Blue' bikini bottoms.

Step 1: Recycling the Bottles

First point of action? Collecting single-use plastic bottles to recycle. On average, each pair of our branded swim shorts saves around 15 plastic bottles from landfill.

Once collected, the bottles are shredded to remove remaining liquid then gently heated until they melt into usable threads. These threads are then strengthened, pulled apart into soft fluff, and reshaped into cloth. After a final process called carding, the fibres are bonded together, and it's on to step 2.

Step 2: Weaving our Recycled Swim Trunks Fabric

Next up, the fibres are spun into a thread before being woven into our high-performance, quick-dry recycled textile. The fabric is then put through a machine which makes it wonderfully soft to touch.

Step 3: Sublimation Printing

It’s now time to add our signature prints. The prints are designed by Oliver, with each telling a story. For the printing, we use a process called sublimation, rather than the traditional dying method, as it's more eco-friendly, using less water and generating minimal waste.

The process is done in Portugal and involves using a special ink that transforms straight from solid to gas when heated, bypassing the liquid stage. In gas form, the ink can fuse deeper into the fabric's fibres. It becomes part of the material instead of just sitting on top. This makes for a soft, breathable fabric for our mens patterned swim shorts that doesn’t crack or fade, no matter how many times you wash and wear.

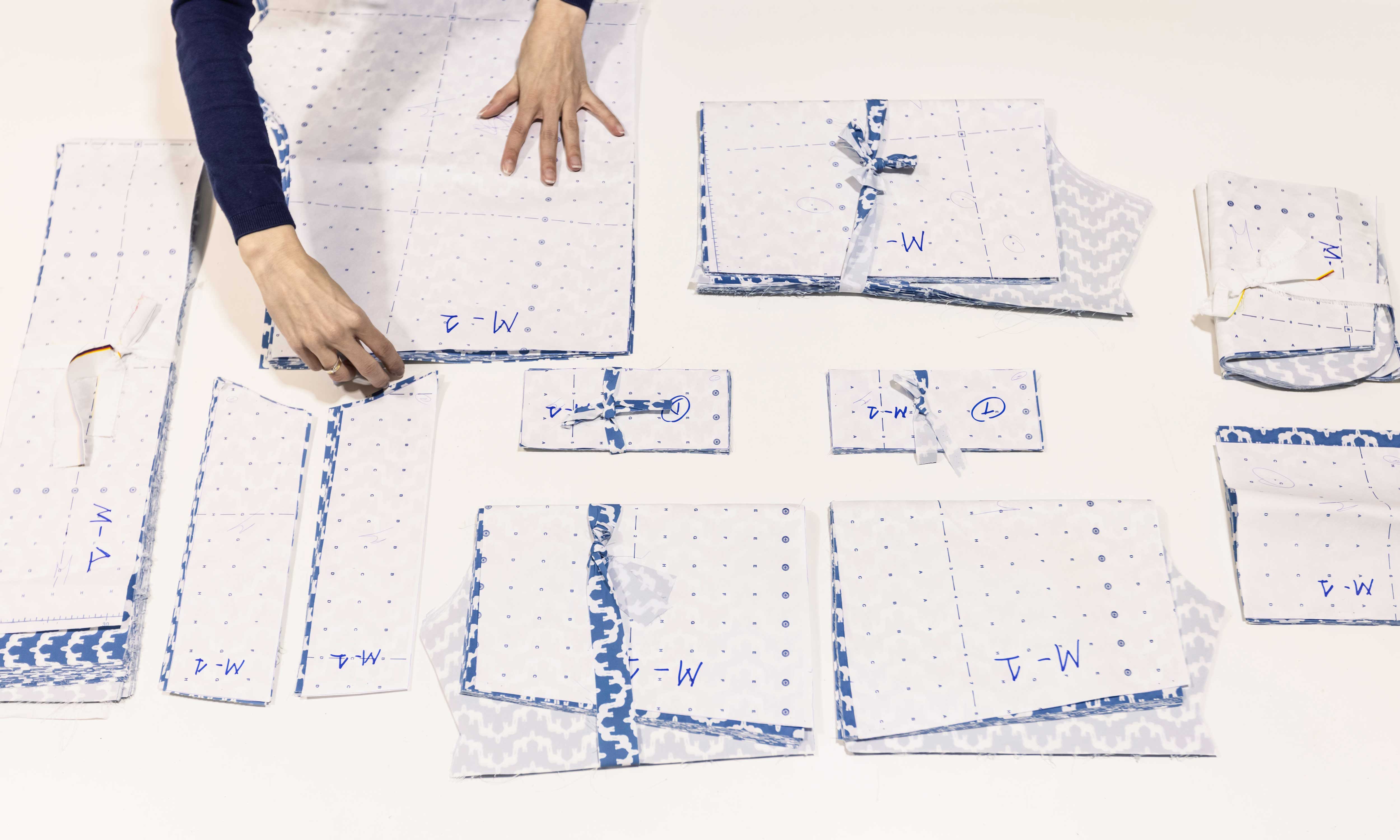

Step 4: Making the Swimming Trunks

Now that we have our beautiful printed fabric, it’s cut into patterns which are then expertly stitched together in our family-run factory in Spain to create our men's bathing trunks. Finally, our side pockets and drawstring are added, as well as our 100% cotton Love Brand label, and your new pair of mens swim trunks are ready to go.

Small Changes, Big Impact

Every purchase of our designer swimming trunks makes a difference. We are a proud member of 1% for the Planet, meaning that at least 1% from every sale goes directly to global conservation projects. So far, we've raised $512,132 (and counting) for charities including Elephant Family, Sheldrick Wildlife Trust and Tusk.

Plus, by choosing recycled swimwear, you’re helping to reduce plastic waste, lower water consumption, and support eco-conscious manufacturing. Each purchase of our swim trunks for men marks a small step toward a cleaner ocean and a greener planet. It's a choice you can feel good about while looking great.

Now, all that’s left to add is you! We’ll see you on the beach, with toes in the sand and a rum dum in hand…